About Us

What You Need to Know About Custom Packaging Boxes – The Ultimate Guide

Views : 15

Update time : 2025-03-03 19:34:00

Why Custom Packaging Matters?

Are you considering investing in custom packaging boxes but feeling overwhelmed by all the choices? Custom packaging is more than just a protective layer—it’s a crucial part of branding, marketing, and customer experience. Well-designed packaging can make your product stand out, attract customers, and enhance brand loyalty. But with so many material, design, and customization options, how do you ensure you’re making the right decisions?

Key Factors in Choosing Custom Packaging Boxes

When selecting custom packaging, focus on key factors like box type, materials, printing methods, finishing techniques, functionality, cost, and sustainability. It’s also crucial to choose a reliable manufacturer who can meet your customization needs. By considering these factors, you can create packaging that not only protects your product but also boosts your brand identity.To help you navigate custom packaging, we’ve compiled a list of nine key questions you should ask before making a decision. Let’s dive into the details.

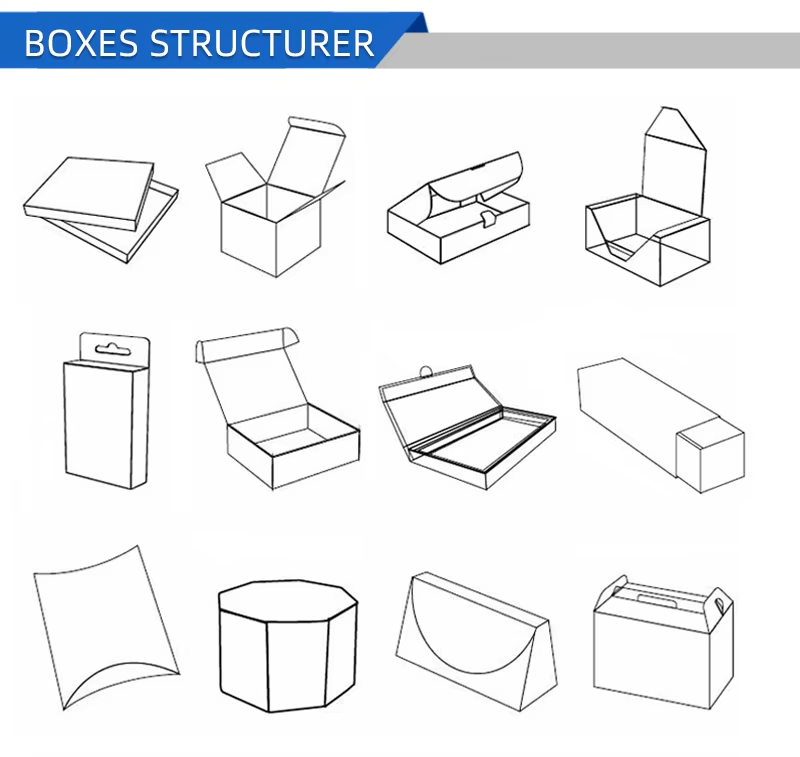

1. What Type of Custom Packaging Box Do You Need?

Choosing the right packaging type depends on your product’s nature, purpose, and brand positioning. Here are some common packaging options:1.1 Folded Packaging Box

• Simple, cost-effective, and widely used.

• Delivered flat and assembled upon use.

• Suitable for a wide range of products like cosmetics, electronics, and gifts.

1.2 Mailer Packaging Box

• Sturdy and protective, ideal for heavy products or items with accessories.

• Often used for subscription boxes and online orders.

• Popular for adult toys like pocket pussies and half-body dolls.

1.3 Gift Packaging Box

• High-end, decorative, and luxurious.

• Great for jewelry, premium sex toys, and branded items.

• Available in various finishes like gloss, matte, or embossing.

1.4 Tube Packaging Box

• Durable, recyclable, and premium-looking.

• Often used for clothing, cosmetics, food, and luxury items.

• Made up of three parts: cylinder body, end cap, and bottom.

1.5 Display Packaging Box

• Designed for retail shelves, exhibitions, and trade shows.

• Enhances brand visibility, sales, and customer attraction.

• Customizable in various shapes, materials, and finishes.

2. What Materials Are Available for Custom Packaging?

Choosing the right material ensures durability, functionality, and a premium feel. Here are some common options:2.1 Standard Paper Options

• White Paper: Available in 200g-400g thickness; commonly used for folding boxes.

• Brown Kraft Paper: Eco-friendly and ideal for sustainable packaging.

• Coated Paper (Clay Coated, Silver, or Golden): Adds a premium feel to packaging.

2.2 Heavy-Duty & Protective Materials

• Corrugated Paper: Offers shock absorption and is great for shipping protection.

• Double-Layer White Paper: Enhances durability, suitable for high-end packaging.

Packaging Tip:

For pocket pussies or half-body dolls, opt for mailer packaging or double-layer folded boxes for extra protection. Vibrators and dildos work well with 350g white paper gift boxes or tube packaging.

3. What Finishing & Craftwork Options Are Available?

Finishing techniques add aesthetic appeal and branding elements to your packaging. Popular options include:• Glossy & Matte Finishes – Simple and cost-effective.

• Embossing & Debossing – Adds a raised or indented texture for a premium touch.

• UV Coating – Enhances design visibility and creates a sleek look.

• Gold & Silver Foiling – Ideal for luxury branding.

4. What Printing Methods Are Available for Packaging?

Your choice of printing method impacts quality, cost, and customization flexibility:• Flexography – Best for high-volume, cost-effective printing.

• Rotogravure – High-end detailed prints, suitable for premium packaging.

• Lithographic (Offset) Printing – High-quality full-color prints but more expensive.

• Digital Printing – Ideal for custom, short-run orders with vibrant colors.

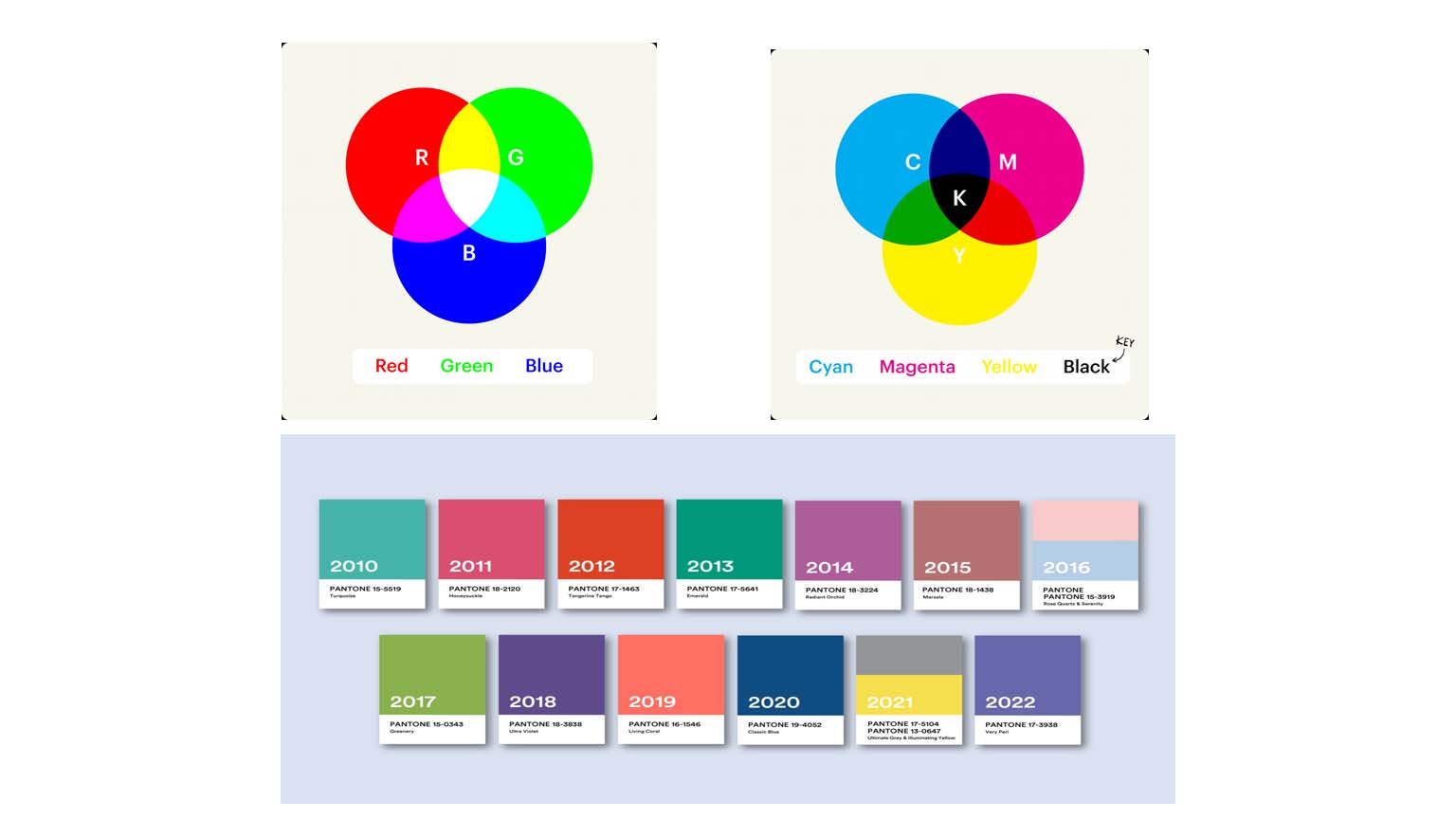

5. What Color Printing Methods Are Available?

• CMYK (Four-Color Printing): Cost-effective, allows full-color prints in one go.• Pantone Color Printing: Ensures exact color matching, but more expensive.

Important: RGB colors aren’t supported for printing as they appear too bright in the final output.

6. How Do You Balance Cost and Quality?

• Compare quotes from multiple manufacturers to find the best deal.• Opt for bulk printing to reduce costs.

• Choose materials that balance affordability and durability—premium materials enhance perceived value.

7. What Functional Aspects Should You Consider?

Beyond aesthetics, think about:• Secure closures & tamper-proof features.

• User-friendly designs (easy to open & reseal).

• Structural stability for shipping protection.

For example, sex toy advent calendars need mailer boxes to securely house multiple items in a set.

8. What Are the Essential Steps in Custom Packaging Production?

1. Design Phase – Work with a designer to create a mock-up.2. Prototype Testing – Order a sample to test material and print quality.

3. Production Approval – Finalize the design and start mass production.

4. Quality Checks – Ensure the packaging meets all requirements before shipping.

9. Why Is Choosing the Right Manufacturer Crucial?

Not all manufacturers offer the same level of quality and service. Before choosing a supplier, consider:• Industry reputation & past customer reviews.

• Ability to meet customization requirements & deadlines.

• Sample testing before bulk orders to ensure quality.

Final Thoughts

Choosing the right custom packaging boxes is essential for product protection, branding, and customer satisfaction. By focusing on materials, box types, finishing, printing, and manufacturing quality, you can create packaging that enhances your brand’s image and appeals to your target market.Ready to create standout packaging? Start by defining your needs and exploring different options to find the perfect fit for your brand.